About Bentonite Powder

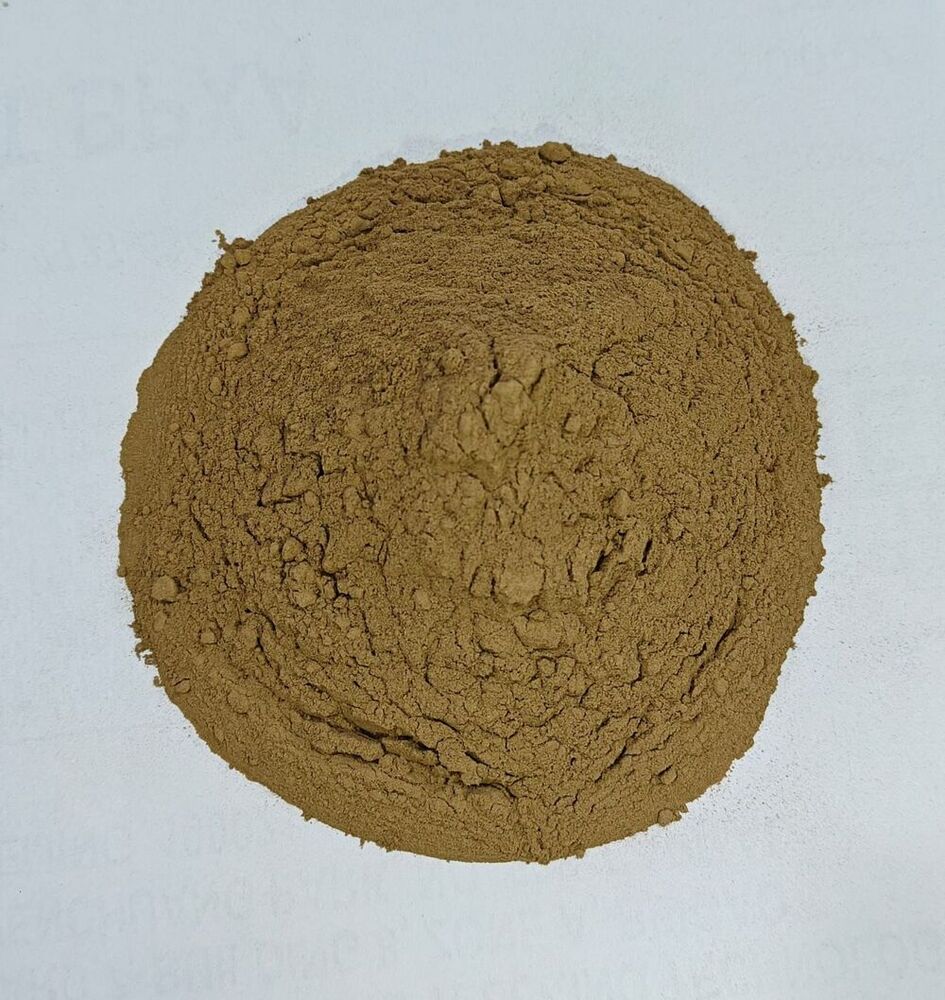

- Bentonite (Calcium Bentonite, Bentonite Cat Litter, Sodium Bentonite)

- Application: Drilling, Foundry, Iron Ore Pelletization, Civil Engineering and others

- Swelling Capacity: High

- Form: Powder/Lumps

- Color: Light to Dark Brown

- Mesh Size: 200

- SUPPLY CAPABILITY: 2000, 500, 2000 Tons Per Month

High Purity and Reliable PerformanceBentonite Powder is engineered to meet a minimum purity of 98%, ensuring minimal impurities for industrial processes. The consistent bulk density and fine mesh guarantee uniformity, supporting efficient usage in metallurgy and other demanding environments. Its significant swelling capacity makes it an effective binder and absorber.

Packaging and Export StandardsPackaged securely in durable bags, our product is easy to transport and store, maintaining its quality from warehouse to application site. As an exporter, manufacturer, and supplier in India, we emphasize strict quality control to deliver Bentonite Powder that aligns with international specifications.

Versatile Industrial ApplicationsWith a pH value ranging from 8.5 to 10 and notable water absorption rates, Bentonite Powder delivers optimal performance in metallurgy and related sectors. Its insolubility in water and light yellow appearance make it suitable for diverse formulations. This ensures users benefit from enhanced process efficiency and product stability.

FAQs of Bentonite Powder:

Q: How is Bentonite Powder used in metallurgical applications?

A: Bentonite Powder acts as a binding agent and purifying material in metallurgy, particularly in pelletizing and casting processes. Its high swelling capacity and water absorption optimize the formation of strong, uniform pellets and enhance impurity removal during smelting.

Q: What are the benefits of Bentonite Powder with a high swelling capacity and water absorption?

A: A swelling capacity of 12 to 15 times and water absorption rate of 600850% enable efficient binding and improved physical strength in processed materials. These properties significantly enhance productivity and product quality in industrial applications.

Q: When should Bentonite Powder be selected over other binding agents?

A: Bentonite Powder is preferred when high purity, excellent swelling performance, and consistent fine particle size are critical. Its insolubility in water and stable bulk density make it a reliable choice for demanding processes such as metallurgy.

Q: Where do you export Bentonite Powder from India?

A: As an exporter, manufacturer, and supplier based in India, we ship Bentonite Powder to global markets, including Asia, Europe, the Middle East, and Africa, supporting various industries with internationally compliant products.

Q: What is the process involved in packaging Bentonite Powder?

A: After quality testing and sizing to 200 mesh, the Bentonite Powder is packed in robust bags to preserve its properties during transportation and storage. This helps prevent contamination and moisture ingress, maintaining product integrity.

Q: How does the powders pH value affect its application?

A: With a pH value of 8.5 to 10, Bentonite Powder ensures stability in alkaline conditions, making it suitable for specialized metallurgical processes where controlled chemical reactivity is necessary.